Crayon Making Machines YouTube

crayon-manufacturing process to better understand what crayons are made from and how they are created in large quantities. Read storybooks about recycling to further their understanding of the process of collection, remanufacture, and using new products made from old (optional). 3. Discuss what natural resource crayons are made from

TIME for Kids to the Crayola Factory!

The fact that the production and consumption of crayons has become very self-sustaining made it difficult to find the actual net wastes that could not be cleaned up. Even in the production process, Crayola uses leftover crayon and paper to make more crayons, so there is not much physical waste that the company reports (Crayola).

Inside the Crayola factory See how the iconic crayons are made NBC News

Take a peek inside a Crayola factory in Easton, Pennsylvania.The INSIDER team believes that life is an adventure! Subscribe to our channel and visit us at: h.

Inside the Rainbow Factory Where Crayola Crayons Are Made WIRED

The first box of Crayolas rolled off the production line 101 years ago, and today the company's Easton, Pennsylvania, factory turns out 12 million crayons a day. "We maintain the process as though.

A BehindtheScenes Look at the Crayola Factory That Produces 12 Million Crayons a Day Crayola

How are Crayola Crayons manufactured and what are the basic ingredients? The basic ingredients contained in Crayola Crayons are paraffin wax and color pigment. The ingredients are the same for all Crayola Crayon colors, with some modifications in special effects crayons.

Inside the Crayola factory where 12m crayons are made every day Daily Mail Online

The process starts with railcars full of paraffin wax. Crayola processes their crayons like they would food, which is good, because crayons are a likely part of most children's diet. Twice a week the railcars of wax are heated with steam by an oil-filled boiler, while workers pump the molten wax into a silo.

The Making of the Crayola Crayon (19 pics)

Here's how Crayola makes the iconic (but inedible) color sticks. 1. Melt Twice a week, railcars full of uncolored paraffin wax pull up to the factory. An oil-filled boiler heats the cars with.

Inside the Rainbow Factory Where Crayola Crayons Are Made WIRED

How are crayons made? The ancient Greeks, Romans and Egyptians had an answer. They used a process of melting beeswax together with a coloured pigment known as encaustic sculpturisation (or hot wax painting) which helped to bind colour to wood, canvas or stone.

Wax Crayons Making Machine in India, Colour Crayon manufacturing Process YouTube

Who manufactured the very first wax crayon is unknown, but a Parisian arts supply manufacturer named Joseph Lemercier is a likely candidate. In the 1820s, his company was producing and selling colored wax crayons [source: Welter].A few years later, in 1835, the German company J. S. Staedler began manufacturing a wax crayon with a wooden casing.

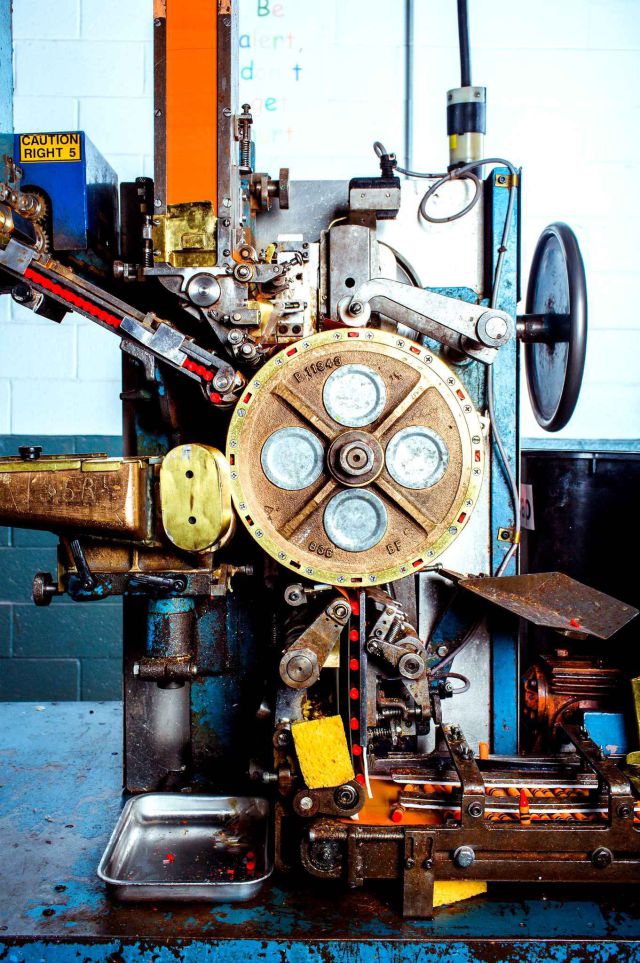

crayon making machinefeeding YouTube

Process Crayon manufacturing is a simple process, but one which is still relatively labor intensive. In the American market, the predominant manufacturer is the Binney & Smith Company of Pennsylvania, which manufactures more than two billion crayons a year. Mixing the batch 1 The paraffin is pumped into supply tanks outside the crayon factory.

Inside the Rainbow Factory Where Crayola Crayons Are Made WIRED

The two basic ingredients for a crayon are: Pigment Paraffin wax, stored in heated 17,000 gallon tanks The mixture is heated until it melts into a liquid. Crayons melt at 105 degrees Fahrenheit (40 degrees Celsius). The mixture is heated to 190 F (82 C). The liquid is poured into a preheated mold full of hundreds of crayon-shaped holes.

How Are Crayons Made Step By Step

By 1958, the company rolled out the 64-color pack with a built-in sharpener. Any former elementary school student remembers how coveted this set of crayons is. The first box of Crayola crayons was made in 1903 and had eight colors. The company began offering a box of 64 crayons (with a built-in sharpener) in 1958. Photos by HA!

Inside the Crayola factory where 12m crayons are made every day Daily Mail Online

Do you want to start a crayon manufacturing business? If YES, here's a complete guide to starting a crayon manufacturing business with NO money and no experience. Starting a manufacturing business needs a lot of dedication and commitment.

Watch the mesmerizing process of how crayons are made

In this episode of "Do You Know?" we delve into the captivating world of manufacturing with our "How It's Made" series. Join us as we take you on a journey t.

Inside the Crayola factory where 12m crayons are made every day Daily Mail Online

Learn how crayons are manufactured. Subscribe to Discovery TV for more great clips:http://www.youtube.com/subscription_center?add_user=DiscoveryTVFollow Disc.

A BehindtheScenes Look at the Crayola Factory That Produces 12 Million Crayons a Day

How are Crayola Crayons manufactured and what are the basic ingredients? The basic ingredients contained in Crayola® Crayons are paraffin wax and color pigment. The ingredients are the same for all Crayola Crayon colors, with some modifications in special effects crayons.